How New Technologies is Changing the Way We Build

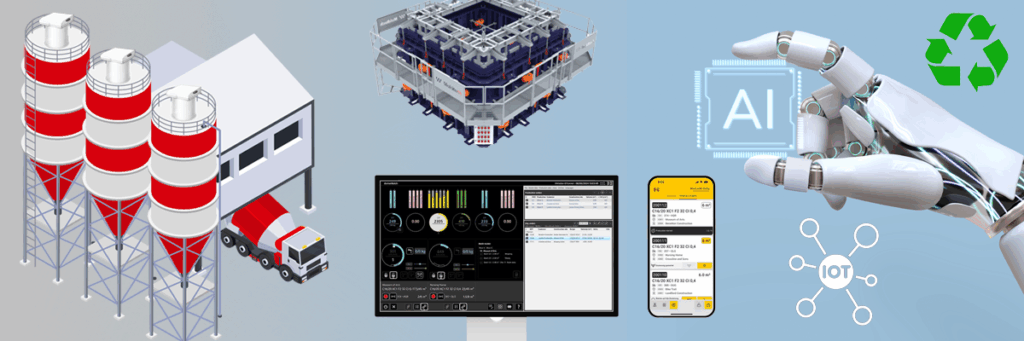

The construction world is changing. Projects are becoming faster, smarter and more environmentally responsible. At the center of it all is the evolution of concrete equipment. The Future of Concrete Equipment is not just about machines—it’s about how technology, efficiency and sustainability come together to reshape construction.

Here are the five key directions shaping this future—and how Deewan Equipment is aligned with each one.

1. Smarter with AI and Automation

Automation is no longer a luxury—it’s a necessity. Advanced concrete batching systems today are integrating artificial intelligence (AI) and automation to improve accuracy, reduce human error, and ensure consistency.

With smart control systems like DornerBatch, batching plants can:

- Automatically adjust concrete mix designs based on materials or weather

- Monitor performance in real time with live dashboards

- Provide remote access and alerts to site managers

- Reduce manpower while increasing production precision

AI-driven batching solutions bring better productivity and transparency to concrete production. This helps avoid delays, ensures uniform quality, and allows smarter planning—all critical in large-scale or time-sensitive projects.

2. Flexible with Mobile and Modular Concrete Plants

Construction sites don’t stay still and equipment shouldn’t either. That’s why mobile and modular batching plants are a big part of the future.

These plants are designed to:

- Be quickly transported and installed at new sites

- Operate in remote or space-constrained areas

- Offer plug-and-play configurations for faster setup

- Scale up or down depending on project size

Deewan provides a range of such solutions ideal for infrastructure development, urban expansion, and emergency projects—where time and mobility are key. This flexibility leads to cost savings and quicker project delivery without compromising quality.

3. Greener with Recycling and Efficiency

Sustainability is more than a trend—it’s a responsibility. The concrete industry is one of the highest producers of CO₂ emissions, so recycling and efficient resource use are essential for future-ready operations.

Advanced concrete recycling systems support this mission by:

- Separating and reusing leftover concrete from mixers

- Filtering and recycling water used in cleaning

- Reducing landfill waste and environmental impact

- Lowering material and disposal costs for contractors

Deewan’s recycling and reclaimer systems are already helping clients reuse their waste efficiently while complying with environmental regulations. These systems not only promote eco-friendly practices but also improve the bottom line.

4. Connected with Smart IoT Technology

Technology is making equipment smarter and safer. With the help of IoT (Internet of Things), concrete equipment can now “talk” to operators, supervisors and even mobile phones.

Smart sensors like the Save & Safe IoT system allow users to:

- Monitor the levels of solid or liquid materials in tanks or silos

- Receive instant alerts before overflow, shortage, or stoppage

- Reduce manual checks and safety risks

- Track equipment use and plan better logistics

Such real-time monitoring makes a big difference on-site. It ensures that material supply runs smoothly, minimizes delays and helps construction teams focus on what matters most—building.

5. Faster Building with Precast Concrete

Speed, precision and consistency—these are the strengths of precast construction. As projects grow larger and timelines get tighter, precast concrete has become an essential part of modern construction methods.

Using factory-made components such as:

- Precast walls, slabs and stairs

- Custom 3D bathroom units (PBU/PPVC)

- Beams and lintels for commercial and residential structures

This approach allows builders to save time, reduce labor costs and maintain quality. It also improves site safety by shifting most of the work offsite. Deewan offers high-performance precast mold systems to support this movement, helping clients adopt faster and cleaner building methods.

A Future Worth Building

The Future of Concrete Equipment is all about combining technology, mobility and sustainability. Whether it’s through AI-powered batching, modular plants, smart sensors, or concrete recycling systems—modern construction depends on smarter tools and smarter thinking.

At Deewan Equipment, we understand where the industry is going—and we’re building the path forward with our clients.